🔹 Fiber Configuration

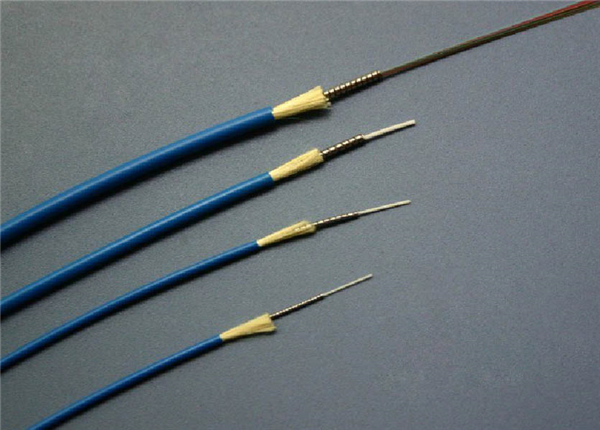

✔ Fiber Count: 2 to 288+ fibers (loose tube, tight-buffered, or ribbon).

✔ Fiber Type:

Single-mode (OS2, G.652.D, G.657.A1/A2) – Long-haul, FTTH, telecom.

Multimode (OM3/OM4/OM5) – Data centers, short-range high-speed networks.

🔹 Jacket & Environmental Protection

✔ Outdoor (PE/PVC/LSZH) – UV, moisture, and abrasion-resistant.

✔ Indoor-Outdoor (Riser/Plenum Rated) – Fire-retardant for building installations.

✔ Oil/Gas Resistant – Special compounds for industrial sites.

✔ Dry Core vs. Gel-Filled – Gel prevents water ingress but requires cleaning; dry core is cleaner.

🔹 Special Requirements

✔ High-Temperature Resistance (up to 200°C for industrial uses).

✔ Anti-Rodent/Anti-Termite Coating (for underground deployments).

✔ Low Smoke Zero Halogen (LSZH) – Safe for confined spaces (tunnels, subways).

✔ Flexible Bend-Optimized (for tight installations, G.657.A2 fibers).

🔹 Leading Manufacturers for Custom Orders

✔ Corning (ALTOS® Armored)

✔ Prysmian Group (Draka® Armored)

✔ CommScope (LightBand® Armored)

✔ OFS (Furukawa)

✔ NEATEL (cost-effective custom solutions)

🔹 Customization Process

✔ Define Requirements (fiber count, environment, armor type, jacket).

✔ Select Fiber Type (SM/MM, bend-insensitive, etc.).

✔ Choose Armor & Jacket (based on crush/rodent/fire resistance needs).

✔ Add Special Features (anti-termite, high-temp, dry core, etc.).

✔ Test & Certify (IEC, UL, RoHS compliance).