🔹 Advantages Over Non-Armored Cables✔ Crush & Rodent Resistance – Survives harsh environments;

✔ UV & Moisture Resistant – Suitable for outdoor/direct burial;

✔ Long Lifespan – 20-30 years in extreme conditions;

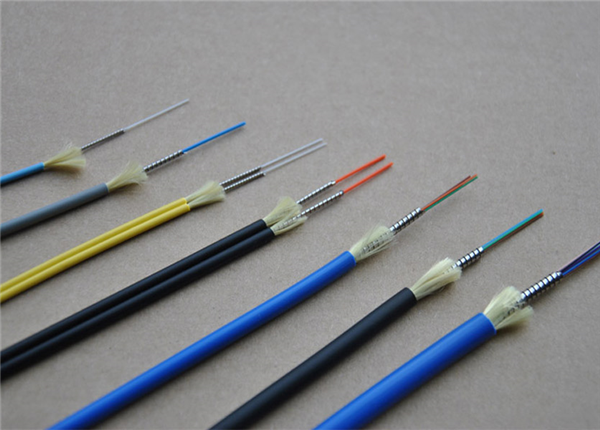

✔ Easy Identification – Often color-coded for fiber management.

🔹 Installation ConsiderationsPulling Tension – Typically 100-300 lbs max (depends on armor type);

Bend Radius – 10x cable diameter (e.g., 20mm cable → 200mm min bend radius);

Termination – Requires armor grounding in patch panels.

🔹 FAQ

🔹 FAQ

Q: Can armored cables be used indoors?

A: Yes, but LSZH-jacketed versions are preferred for fire safety.

Q: How to terminate armored fiber cables?

A: Strip outer jacket & armor.

Ground the armor (if required).

Splice or connectorize fibers (using fusion/mechanical splicing).

Q: What’s the cost difference vs. non-armored?

A: ~20-50% more expensive, but justified for harsh environments.