ADSS cables are all-dielectric (non-metallic) and self-supporting, meaning they require no separate messenger wire or support strand. They are designed for aerial installation on utility poles or transmission towers.

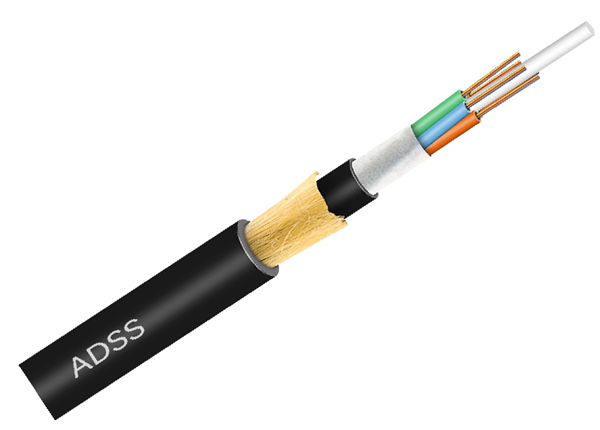

The typical construction includes

✅ Loose tube design: Optical fibers are housed in water-blocked loose tubes (often filled with gel or waterproof compounds) for protection against moisture and mechanical stress.

✅ Strength members: Aramid yarns (e.g., Kevlar) or fiberglass reinforced plastic (FRP) are used for tensile strength.

✅ Jacket layers: Usually double-jacketed—inner polyethylene (PE) sheath and outer PE or (AT) sheath for higher voltage environments (e.g., >12 kV).

| Fiber Count | 4 - 12 |

| Fiber Type | Single mode G.652.D |

| Strength Member | Two Parallel FRP |

| Loose Tube | PBT |

| Filler Rope | No |

| Water Blocking Layer (Material) | Water Blocking tape |

| Outer Sheath | PE |

| Tension | 1500N |

| Crush (N/100MM) Short Term | 2200N |

| Crush (N/100MM) Long Term | 1100N |

| Cable Diameter (±0.2mm) | 6.8mm;8.0mm;8.5mm |

| Cable Weight (±10.0kg/km) | 60-70kg |

| Attenuation coefficient | @ 1310nm≤0.35dB; @ 1550nm ≤0.2dB |

| Install Temperature | -40~60℃ |